The single shaft Plastic Shredder is designed to process with tough ,hard and solid plastics lumps ,also such as large thick pipes, buckets, pallets,rubber, wood, etc. Working with medium speed , low noise, low power consumption. Rotary blades has 4 sides can be exchanged four times for use, which prolong using life. When push materials by hydraulic, can select speed and presure freely according to different materials load. It is with low labor strength, safe& reliable operation.

| Model | GLSS-600 | GLSS-800 | GLSS-1000 | GLSS-1200 | GSS-1500 |

| Main Motor Power(kw) | 22 | 37 | 45 | 55 | 75 |

| Hydraulic Motor Power(kw) | 2.2 | 3 | 3 | 5.5 | 5.5 |

| Cylinder Stroke(mm) | 750 | 850 | 900 | 1000 | 1000 |

| Rotor Diameter (mm) | Φ300 | Φ400 | Φ400 | Φ400 | Φ450 |

| Main Shaft Speed(r/min) | 83.7 | 87.5 | 73.5 | 73.5 | 83.3 |

| Screen Mesh(mm) | Φ50 | Φ50 | Φ55 | Φ55 | Φ55 |

| Rotating Blades(PCS) | 26+4 | 42+4 | 54+4 | 66+4 | 84+4 |

| Fixed Blades(PCS) | 4 | 4 | 2 | 2 | 3 |

| Dimenesion(mm) | 2400*1400*1700 | 2800*1700*1800 | 2800*2000*1800 | 2800*2500*1800 | 2800*3000*2200 |

| Weight(KG) | 1650 | 3400 | 4400 | 6000 | 8000 |

The main shaft is high-strength solid shaft. The rotor blade adopts square design, which can be used on all four sides. After one side is worn, can be used on another side, prolong the blade service life. The blades are fix on the shaft in a V-shaped arrangement ,also may adopt different design according to the material condition and customized demand!

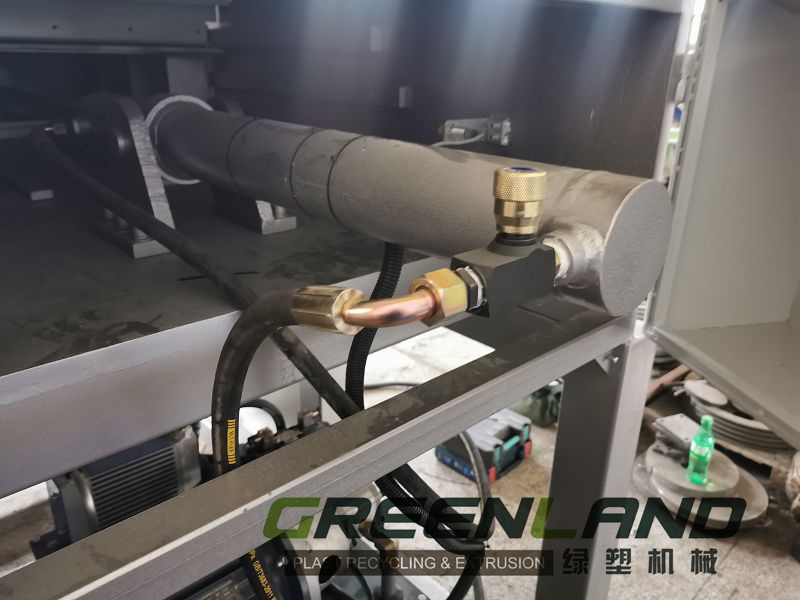

The bearing block is installed outside the shredding chamber, effectively prevent particles of crushed material in the crushing chamber entering into bearing house, so that improve the bearing life. set up regular adding oil nozzle

Automatic hydraulic pushing system, repeatedly push the material to the rotating blade shaft.Automatical reverse rotate and back,easy and safe operation.

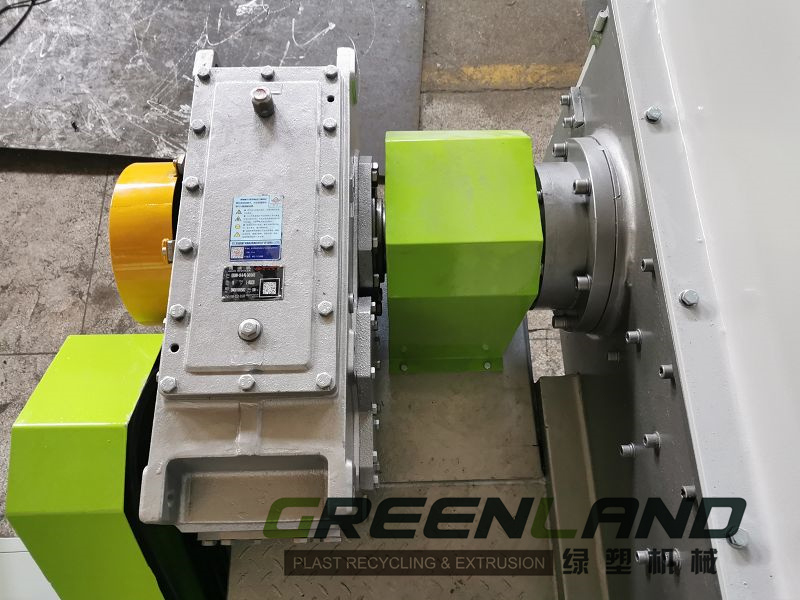

Using hardened teeth gearbox, safe and stable.

Absorb the vibration generated during the shredding process ,to make it shred smoothly.

Different screen sizes and designs ,to meet different customer needs

Safe, intelligent, install instant overload shutdown protection device, the blade shaft automatically stop and then reverses

If you have other questions, please contact us

Send me your demands by email or whatsapp, we will get back recommend suitable project solution and quote accordingly.

We send detailed machine quotation to you, if you are satisfied, we will make contract for you. Payment terms: T/T, L/C

In some countries, we have agent. We have one-year warranty.

You are welcomed to ask authority agency to visit our factory and machine.

We can assign engineer to your factory to install the machine and offer training. Each year, if we have machine technical improvements, we will inform customer.

Our factory is located in Zhangjiagang city which is nearby Shanghai port, about 2.5 hours car driving. If you want to visit our factory, we can come to pick you up.

Copyright © 2022.ZHANGJIAGANG GREENLANDPLAST MACHINERY CO.,LTD All Rights Reserved

The email will be sent directly to our CEO Bruce