The GL-B series agglomerating/compacting Plastic Pelletizing Machine combines function of crushing,compacting,and pelletizing to one-stop ,applied in the plastic films, plastic bags ,raffia bags, non-woven material , filaments,and foamed materials recycling and pelletizing. and pelletizing process,which is a reliable and efficiency solution .

Final product pellets/ granules produced by this machine, can directly be used in the production line for film blowing, pipe extrusion and plastics injection, etc

HDPE LDPE LLDPE PP PS PLA PET and more . For example ,packaging films &bags , PP woven /raffia ,factory edge-trimmed cutting materials,waste fiber

| Model | Screw Diameter (mm) | L/D | Motor power | Capacity |

| GLAP-80 | 80 | 33 | 37/55kw | 120-200kgh |

| GLAP-100 | 100 | 33 | 55/75kw | 200-350kgh |

| GLAP-120 | 120 | 33 | 90/132kw | 350-600kgh |

| GLAP-140 | 140 | 33 | 110/160kw | 600-750kgh |

| GLAP-160 | 160 | 33 | 132kw/220kw | 750-900kgh |

| GLAP-180 | 180 | 33 | 185kw/250kw | 900-1000kgh |

Plastic material be conveyed into the compactor/agglomerate chamber by belt conveyor,as to rolls films ,roller hauling feeding system may be installed as optional !Feeding speed are frequency controlling,speed is automatic adjusting based on how full compactor chamber is! Metal detector can be combined with belt conveyor

The rotatory blades of compactor crush incoming material into scraps,at the same time ,frictional heating which caused by high speed rotation will heat and let scraps shrinking ,the material and directs it into extruder screw barrel by balde plate base rotation centrifugal force .Compactor with air cooling &water cooling function ,automatic water water spray cooling technology,to cool down material and avoid over heated.

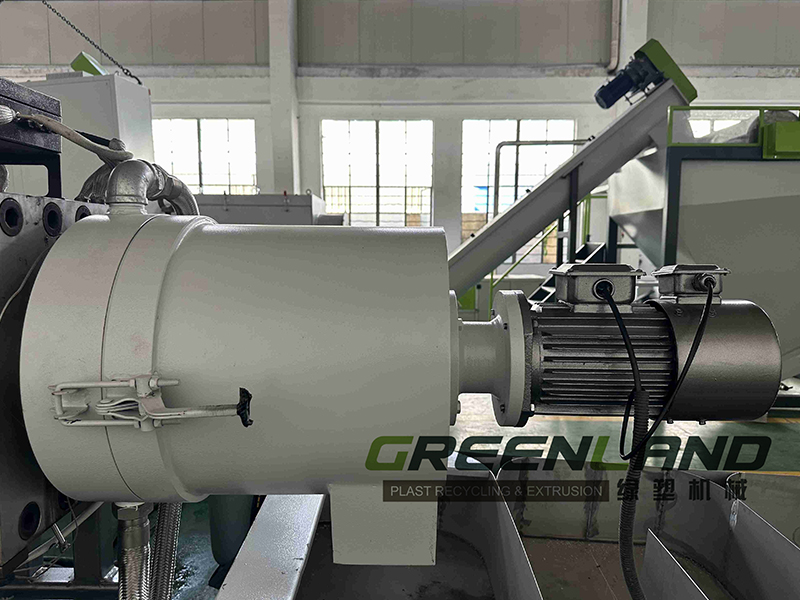

Screw &barrel 38CrMoAl screw&barrel nitrogen treatment,the surface of screw is sprayed with alloy wear layer, double vacuum exhaust,more effectively remove moisture from the material to ensure pellets quality

Equip hydraulic automatic non-stop screen changing filter system,with automatic pressure alarm device

Water-ring die-head cutting type, cutting speed frequency controlling ,SKD material blade,pellets size uniform and beautiful

Vibration dewatering method, saving power consumption and low noise,high performance of pellets dewatering drying !

Pellets be conveyed to the storage tank by air blower. The air conveyor pipe and the sotrage silo are made of stainless steel, and the air conveyor pipe is equipped with sound-absorbing cotton to reduce noise.

If you have other questions, please contact us

Send me your demands by email or whatsapp, we will get back recommend suitable project solution and quote accordingly.

We send detailed machine quotation to you, if you are satisfied, we will make contract for you. Payment terms: T/T, L/C

In some countries, we have agent. We have one-year warranty.

You are welcomed to ask authority agency to visit our factory and machine.

We can assign engineer to your factory to install the machine and offer training. Each year, if we have machine technical improvements, we will inform customer.

Our factory is located in Zhangjiagang city which is nearby Shanghai port, about 2.5 hours car driving. If you want to visit our factory, we can come to pick you up.

Copyright © 2022.ZHANGJIAGANG GREENLANDPLAST MACHINERY CO.,LTD All Rights Reserved

The email will be sent directly to our CEO Bruce