*This plastic pelletizing line is mainly used for the recycling granulation/pelletizing of rigid regrind flakes material ,it can also be used for washing and drying regrind flakes , squeezed and compacted film materials and the semi-plasticized materials after agglomeration. By equipping with different feeding methods and pelletizing methods, installating forced feeding system can also be used for pelletizing of film crushed scraps. It can be suitable for recycling and pelletizing of various types and properties material, such as PE, PE, ABS, PS , PC, PA, PVC and other materials.

*The recycled plastic material are usually conveyed by screw feeder or belt conveyor into extrusion system, then the material are fed to the extruder screw barrel through a quantitfy feeding device. The screw is specially designed for the recycled material recycling pelletizing , and has advantage of fast feeding&stable and resistance. With natural venting and vacuum system; can effectively discharge the water inside the material; the extruder uses cast aluminum heaters or ceramic heater, durable. Customers aso may choose two-stage pelletizing system, use the two extruders pass the secondary filtration to make the pellets be cleaner and higher quality;

PE,PP,HIPS,ABS,PC,etc., crushed granules and plastic flakes.

| Model | Screw Diameter(mm) | L/D | Motor Power | Capacity |

| GLP100-100 | 100 | 25-33:1&10-12:1 | 55/22kw | 150-200kgh |

| GLP120-120 | 120 | 25-33:1&10-12:1 | 90/37kw | 250-350kgh |

| GLP140-140 | 140 | 25-33:1&10-12:1 | 132/55kw | 400-500kgh |

| GLP160-160 | 160 | 25-33:1&10-12:1 | 160/75kw | 550-650kgh |

| GLP180-180 | 180 | 25-33:1&10-12:1 | 185/90kw | 650-800kgh |

| GLP200-200 | 200 | 25-33:1&10-12:1 | 250/110kw | 800-1000kgh |

The material is fed to the extrusion system through a screw feeder or a belt conveyor, the belt conveyor may be equipped with metal detector as optional.

The feeding speed is frequency control by inverter , to be adapt to different properties material and to ensure the stable operation of the extruder .

The feeding system is equipped with sensor device, which is synchronized with the loading system to realize intelligent automatic feeding. The feeding system stops feeding when the material is full, and automatically loads when the material is not full.

The screw barrel of the extruder is specially designed for plastic recycling pelletizing. It is made of 38CrMoAl material with nitrided treatment, the surface of the screw is sprayed with alloy wear-resistant layer. The barrel is equipped with exhaust section.,extruder is equipped with vacuum exhaust . has the advantages of high output, excellent dehydration and exhaust effect, and wear resistance.

The heating system adopts cast aluminum heater or ceramic heater. Each heating zone has an independent intelligent temperature control system and equipped with forced air cooling. The temperature control is convenient and accurate, which is more conducive to the pellets quality

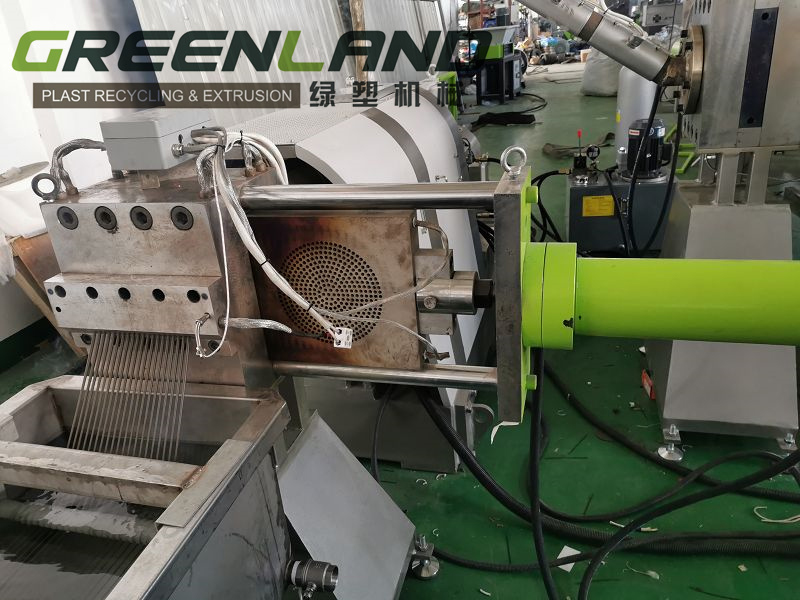

Usually filter system adopt plate-type hydraulic automatic screen changer ,to filter small impurities in the material and improve the pellets quality , it is equipped with automatic pressure alarm device.

According to customer requirements, we also may equip column hydraulic screen changer or non-net screen changer ,to improve the filtering effect and facilitate operation.

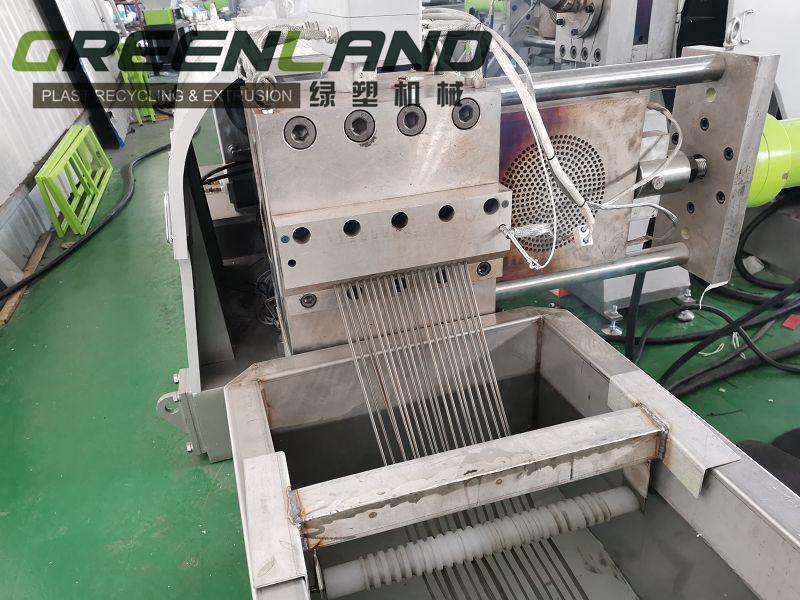

The water cooling noodle cutting eplletizing production line can convert waste plastics into recycled plastic pellets. The most traditional and common method of plastic recycling pelletizing, low-cost and easy to operate. Especially be used for some materials that are not suitable for water ring cutting, such as ABS, PET

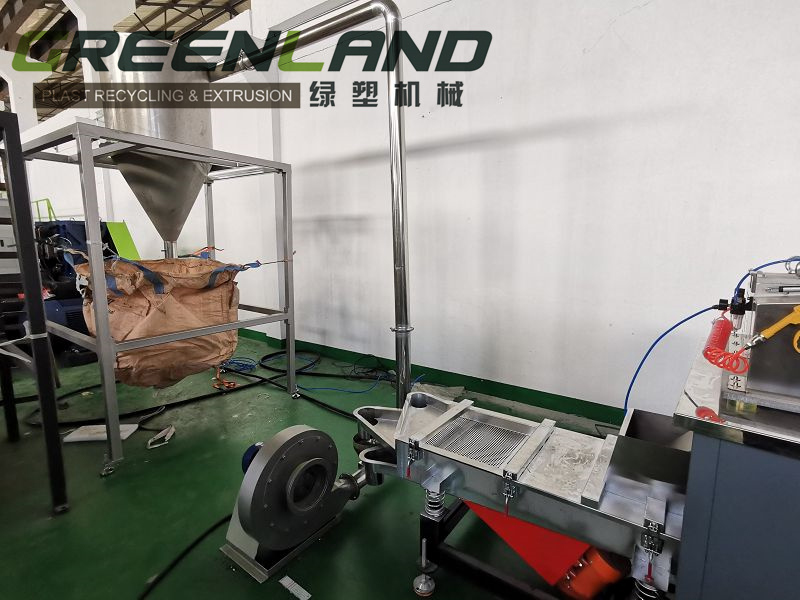

Using forced air cooling to dry plastic strips, the vibrating screen can screen out particles with uneven cutting and further cool the particles

If you have other questions, please contact us

Send me your demands by email or whatsapp, we will get back recommend suitable project solution and quote accordingly.

We send detailed machine quotation to you, if you are satisfied, we will make contract for you. Payment terms: T/T, L/C

In some countries, we have agent. We have one-year warranty.

You are welcomed to ask authority agency to visit our factory and machine.

We can assign engineer to your factory to install the machine and offer training. Each year, if we have machine technical improvements, we will inform customer.

Our factory is located in Zhangjiagang city which is nearby Shanghai port, about 2.5 hours car driving. If you want to visit our factory, we can come to pick you up.

Copyright © 2022.ZHANGJIAGANG GREENLANDPLAST MACHINERY CO.,LTD All Rights Reserved

The email will be sent directly to our CEO Bruce