Feeding

Plastic material be conveyed into the compactor/agglomerate chamber by belt conveyor,as to rolls films ,roller hauling feeding system may be installed as optional !Feeding speed are frequency controlling,speed is automatic adjusting based on how full compactor chamber is! Metal detector can be combined with belt conveyor

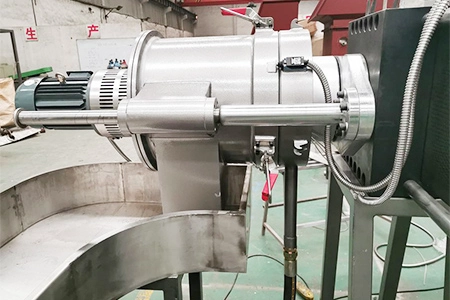

Agglomerating/Compacting chamber

The rotatory blades of compactor crush incoming material into scraps,at the same time ,frictional heating which caused by high speed rotation will heat and let scraps shrinking ,the material and directs it into extruder screw barrel by balde plate base rotation centrifugal force .Compactor with air cooling &water cooling function ,automatic water water spray cooling technology,to cool down material and avoid over heated.

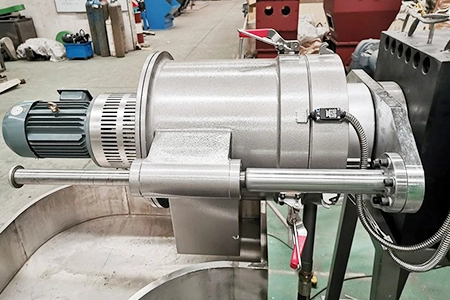

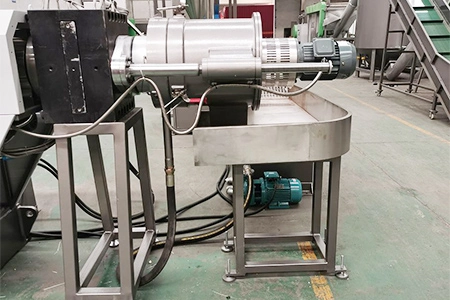

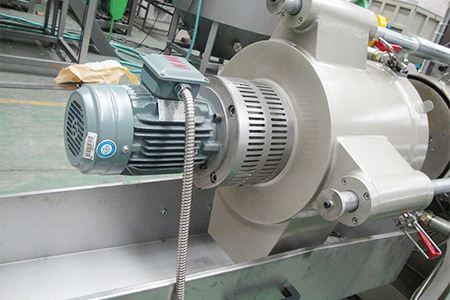

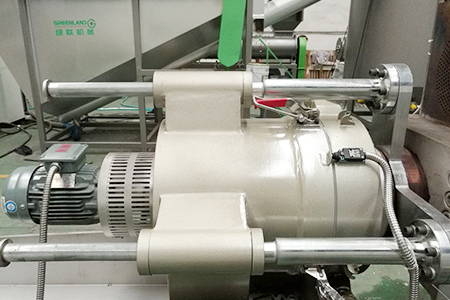

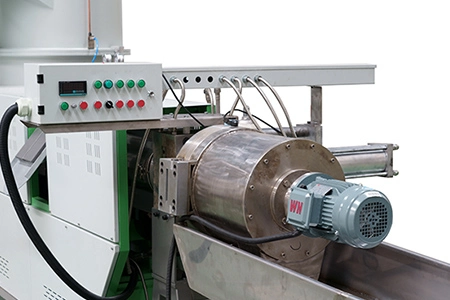

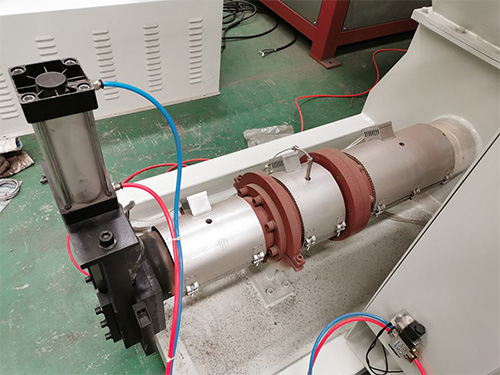

Extrusion pelletizing system

Screw &barrel 38CrMoAl screw&barrel nitrogen treatment,the surface of screw is sprayed with alloy wear layer, double vacuum exhaust,more effectively remove moisture from the material to ensure pellets quality

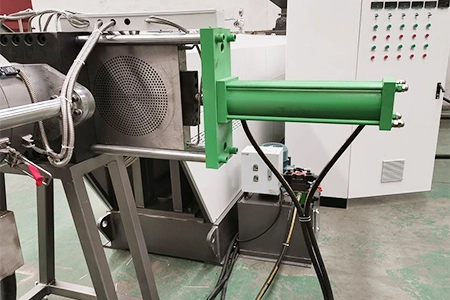

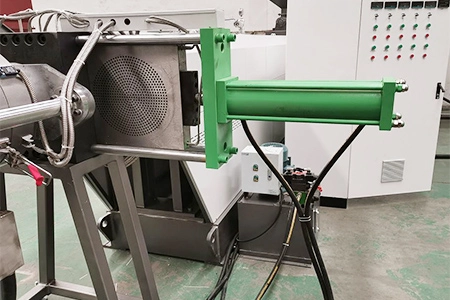

Hydryalic screen changing/ filter system

Equip hydraulic automatic non-stop screen changing filter system,with automatic pressure alarm device

Cutting pelletizing system

Water-ring die-head cutting type, cutting speed frequency controlling ,SKD material blade,pellets size uniform and beautiful

Dewatering drying system

Vibration dewatering method, saving power consumption and low noise,high performance of pellets dewatering drying !

Air conveyor& storage system

Pellets be conveyed to the storage tank by air blower. The air conveyor pipe and the sotrage silo are made of stainless steel, and the air conveyor pipe is equipped with sound-absorbing cotton to reduce noise.

Loading system

*The material is fed to the extrusion system through a screw feeder or a belt conveyor, the belt conveyor may be equipped with metal detector as optional.

Quantitative feeding system

*The feeding speed is frequency control by inverter , to be adapt to different properties material and to ensure the stable operation of the extruder .

*The feeding system is equipped with sensor device, which is synchronized with the loading system to realize intelligent automatic feeding. The feeding system stops feeding when the material is full, and automatically loads when the material is not full.

Extrusion sytem

The screw barrel of the extruder is specially designed for plastic recycling pelletizing. It is made of 38CrMoAl material with nitrided treatment, the surface of the screw is sprayed with alloy wear-resistant layer. The barrel is equipped with exhaust section.,extruder is equipped with vacuum exhaust . has the advantages of high output, excellent dehydration and exhaust effect, and wear resistance.

The heating system adopts cast aluminum heater or ceramic heater. Each heating zone has an independent intelligent temperature control system and equipped with forced air cooling. The temperature control is convenient and accurate, which is more conducive to the pellets quality

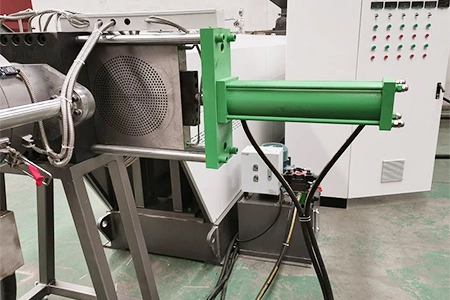

Screen change filter system

*Usually filter system adopt plate-type hydraulic automatic screen changer ,to filter small impurities in the material and improve the pellets quality , it is equipped with automatic pressure alarm device.

*According to customer requirements, we also may equip column hydraulic screen changer or non-net screen changer ,to improve the filtering effect and facilitate operation.

Pelletizer cutting system

*Greenlandplast waste plastic recycling pelletizing/granulator usually adopts water ring pelletizing system, the pelletizing effect is smooth and beautiful, easy to operate, and save labor.

*According to the special properties of certain materials and customer choices, we can also equip water-stretching and pelletizing, automatic strand-stretching and pelletizing or underwater pelletizing systems.

Vibration dewatering system

Vibration dewatering method with dewatering fan, save power consumption, low noise, excellent particle dewatering and drying effect.

Air conveyor&hopper storage

Air conveyor is used to transfer pellets to the storage tank. The air conveyor pipe and the tankare made of stainless steel, and pipe surface is equipped with sound-absorbing cotton to reduce noise.

Loading system

*The material is fed to the extrusion system through a screw feeder or a belt conveyor, the belt conveyor may be equipped with metal detector as optional.

Quantitative feeding system

*The feeding speed is frequency control by inverter , to be adapt to different properties material and to ensure the stable operation of the extruder .

*The feeding system is equipped with sensor device, which is synchronized with the loading system to realize intelligent automatic feeding. The feeding system stops feeding when the material is full, and automatically loads when the material is not full.

Extrusion sytem

The screw barrel of the extruder is specially designed for plastic recycling pelletizing. It is made of 38CrMoAl material with nitrided treatment, the surface of the screw is sprayed with alloy wear-resistant layer. The barrel is equipped with exhaust section.,extruder is equipped with vacuum exhaust . has the advantages of high output, excellent dehydration and exhaust effect, and wear resistance.

The heating system adopts cast aluminum heater or ceramic heater. Each heating zone has an independent intelligent temperature control system and equipped with forced air cooling. The temperature control is convenient and accurate, which is more conducive to the pellets quality

Screen change filter system

*Usually filter system adopt plate-type hydraulic automatic screen changer ,to filter small impurities in the material and improve the pellets quality , it is equipped with automatic pressure alarm device.

*According to customer requirements, we also may equip column hydraulic screen changer or non-net screen changer ,to improve the filtering effect and facilitate operation.

Pelletizer cutting system

*Greenlandplast waste plastic recycling pelletizing/granulator usually adopts water ring pelletizing system, the pelletizing effect is smooth and beautiful, easy to operate, and save labor.

*According to the special properties of certain materials and customer choices, we can also equip water-stretching and pelletizing, automatic strand-stretching and pelletizing or underwater pelletizing systems.

Vibration dewatering system

Vibration dewatering method with dewatering fan, save power consumption, low noise, excellent particle dewatering and drying effect.

Air conveyor&hopper storage

Air conveyor is used to transfer pellets to the storage tank. The air conveyor pipe and the tankare made of stainless steel, and pipe surface is equipped with sound-absorbing cotton to reduce noise.

nihao

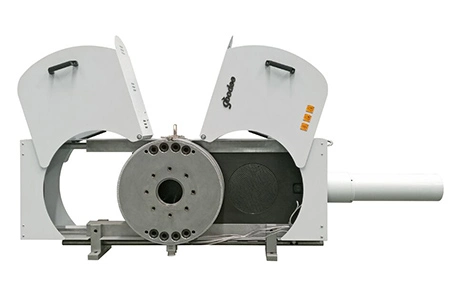

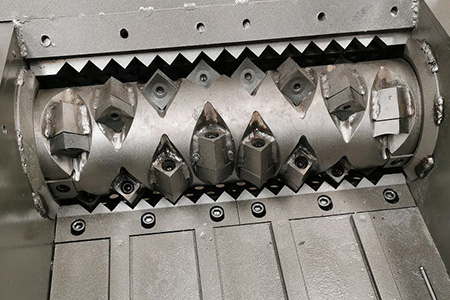

Main shaft &blades

The main shaft is high-strength solid shaft. The rotor blade adopts square design, which can be used on all four sides. After one side is worn, can be used on another side, prolong the blade service life. The blades are fix on the shaft in a V-shaped arrangement ,also may adopt different design according to the material condition and customized demand!

Bearing

The bearing block is installed outside the shredding chamber, effectively prevent particles of crushed material in the crushing chamber entering into bearing house, so that improve the bearing life. set up regular adding oil nozzle

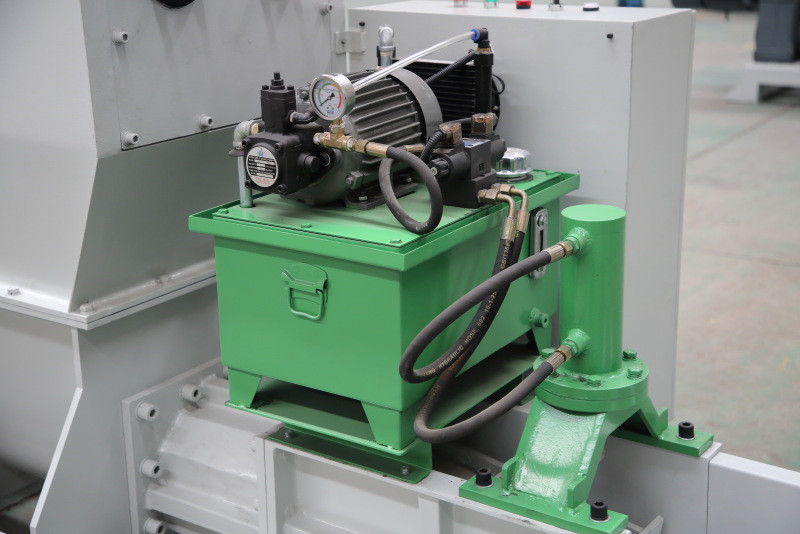

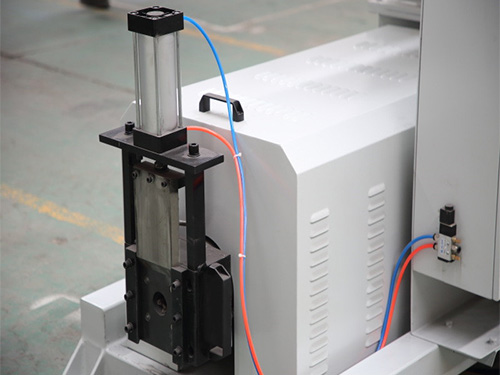

Hydraulic pushing system

Automatic hydraulic pushing system, repeatedly push the material to the rotating blade shaft.Automatical reverse rotate and back,easy and safe operation.

Gearbox

Using hardened teeth gearbox, safe and stable.

Shock Absorber

Absorb the vibration generated during the shredding process ,to make it shred smoothly.

Screen

Different screen sizes and designs ,to meet different customer needs

Control system

Safe, intelligent, install instant overload shutdown protection device, the blade shaft automatically stop and then reverses